In the world of surface preparation, shot blasting plays a vital role in achieving perfect finishes, extending component lifespan, and ensuring product reliability. But the real difference between a mediocre result and a professional finish often comes down to one thing — the quality of your shot blast medium. Whether you’re looking for grit, bead, or any other shot blast medium, Stacey’s stock and expertise ensure your project gets the best product at the right grade.

At Stacey-Processing, we’ve built our reputation around one simple promise — delivering the highest-quality blasting materials, perfectly matched to each customer’s unique requirements. From heavy-duty steel grit to delicate glass beads, our vast inventory and decades of know-how make us one of the UK’s most trusted names in surface preparation.

A Complete Range of Shot Blast Mediums

Every surface, every material, and every outcome requires a specific blasting solution. That’s why Stacey-Processing offers a full spectrum of blasting materials designed for precision and performance. Our range includes:

- Steel Grit and Steel Shot – Known for their aggressive cleaning and long lifespan, ideal for tough surface preparation tasks in heavy engineering and shipyards.

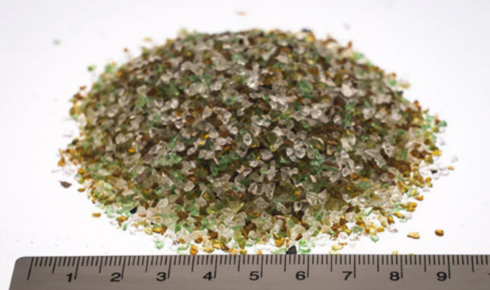

- Glass Bead – Perfect for creating smooth, polished finishes on stainless steel, aluminium, and other non-ferrous metals.

- Aluminium Oxide and Garnet Grit – Preferred for their sharp cutting action and consistent particle size, making them a go-to for coating preparation.

- Plastic and Ceramic Media – Essential for delicate applications where precision cleaning without surface damage is crucial.

So, whether you’re looking for grit, bead, or any other shot blast medium, Stacey-Processing has the right solution for every challenge — all available in the correct grade and specification.

Expert Guidance for Every Application

Selecting the correct shot blast medium isn’t just about choosing the right material — it’s about understanding how different grades, hardness levels, and densities interact with your substrate. This is where our in-house expertise truly shines.

Our technical specialists work closely with clients across industries such as automotive, aerospace, foundry, and fabrication. They help determine the most effective blasting media for each process, balancing cost, performance, and finish quality. Whether you need a coarse grit for rapid rust removal or fine beads for a cosmetic finish, Stacey-Processing ensures your choice delivers consistent, repeatable results.

As we like to say: Whether you’re looking for grit, bead, or any other shot blast medium, Stacey’s stock and expertise ensure your project gets the best product at the right grade. That isn’t just a slogan — it’s how we operate daily.

Quality and Consistency You Can Trust

Every bag, drum, or pallet of shot blast medium that leaves our facility undergoes strict quality checks. We only source from proven, reputable manufacturers, ensuring that each grain or bead meets precise size and hardness tolerances. This commitment to quality is what keeps our clients returning — they know that when they order from Stacey-Processing, they receive consistency batch after batch.

Moreover, our team ensures compliance with industry standards and environmental best practices. We actively promote media recycling and recovery wherever possible, helping customers reduce waste and operational costs.

Tailored Supply Solutions for Every Business

We understand that every operation is unique. That’s why Stacey-Processing provides flexible supply options — from one-off orders to long-term contracts for large-scale production lines. Our stock management systems ensure quick turnaround and reliable delivery schedules, helping you maintain smooth production flow without delays.

And because we maintain an extensive on-site inventory, we’re always ready to dispatch even the most specific shot blast medium at short notice. This means less downtime for your business and more time achieving high-quality results.

The Stacey-Processing Difference

What sets Stacey-Processing apart isn’t just our comprehensive stock — it’s our people. Our experienced team combines decades of industry knowledge with hands-on practical experience. We pride ourselves on being more than suppliers; we’re partners in your process improvement.

From helping new clients identify the right grit or bead type to troubleshooting issues in established systems, our experts provide guidance that directly improves blasting efficiency, reduces wear on equipment, and enhances surface quality.

Our philosophy is simple: provide premium materials, expert advice, and exceptional service — all backed by a genuine understanding of what our customers need to succeed.

Meeting Modern Industry Standards

With growing demand for sustainability and precision manufacturing, Stacey-Processing continuously invests in technology, training, and quality assurance. Our shot blast medium solutions meet modern industry standards for performance and environmental responsibility.

We also help customers transition to more efficient and eco-friendly blasting options, ensuring they meet compliance requirements while maintaining the same, if not better, surface results. This commitment to innovation ensures our clients stay ahead — and their components look better, last longer, and perform at their best.

Why Choose Stacey-Processing?

- Comprehensive Range – Grit, bead, and all other shot blast media in multiple grades and sizes.

- Trusted Expertise – Decades of hands-on experience and technical support.

- Consistent Quality – Strict quality control ensures reliable, repeatable performance.

- Rapid Delivery – Large inventory and quick dispatch times.

- Customer Commitment – Personalised service and long-term relationships.

At every step, we uphold the core value of our promise: Whether you’re looking for grit, bead, or any other shot blast medium, Stacey’s stock and expertise ensure your project gets the best product at the right grade.

Ready to Get Started?

If you’re looking for a reliable partner to supply your blasting materials — one that truly understands your process — then look no further than Stacey-Processing. Our team is ready to help you choose the right shot blast medium for your exact needs.